EP #43 – Virtual Inspections Explained By An Ex-Gas Safe Inspector w/ Terry Sawyer

Overview

In this episode of The Gas Engineer Podcast, host Tulloch Priest speaks with Terry Sawyer, a highly experienced gas engineer and former Gas Safe inspector, about what really happens during an inspection and how to prepare for it.

From the rise of virtual inspections to what actually triggers a face-to-face visit, Terry breaks down every step of the process.

Highlights

What are virtual inspections?

- (1:35) Terry walks through the three types of inspections: In-person on the job, group/conference type inspections, and virtual inspections.

- (2:21) Virtual inspections are a little different to in-person inspections. They’re focused on knowledge of unsafe situations and technical bulletins, rather than practical work.

- (3:30) Virtual inspections are aimed at those who have had in-person inspections before.

- (4:10) If you fail a virtual inspection, you are often given a second chance with an in-person inspection.

- (5:30) In-person inspections are nice because inspectors can walk through what the engineer got wrong, and it becomes more of a learning opportunity.

Where engineers go wrong

- (6:50) Complaints do get made because people can be overly-cautious, capping off boilers that are at risk.

- (8:30) Keep all the documentation on hand as you do an inspection (virtual included), as you can refer to it during the inspection.

- (9:15) Gas Safe are more than happy to accommodate your needs. If you want an in-person inspection rather than a virtual inspection, just ask for it.

- (9:55) Terry explains how in-person inspections work.

- (10:30) Technical bulletins are there for your information, but you don’t necessarily need to know them all.

- (14:30) There are grey areas that not even all inspectors agree on.

- (15:50) The Registered Gas Engineer magazine (and others) contains some good information on regulatory updates.

Preparing for an inspection

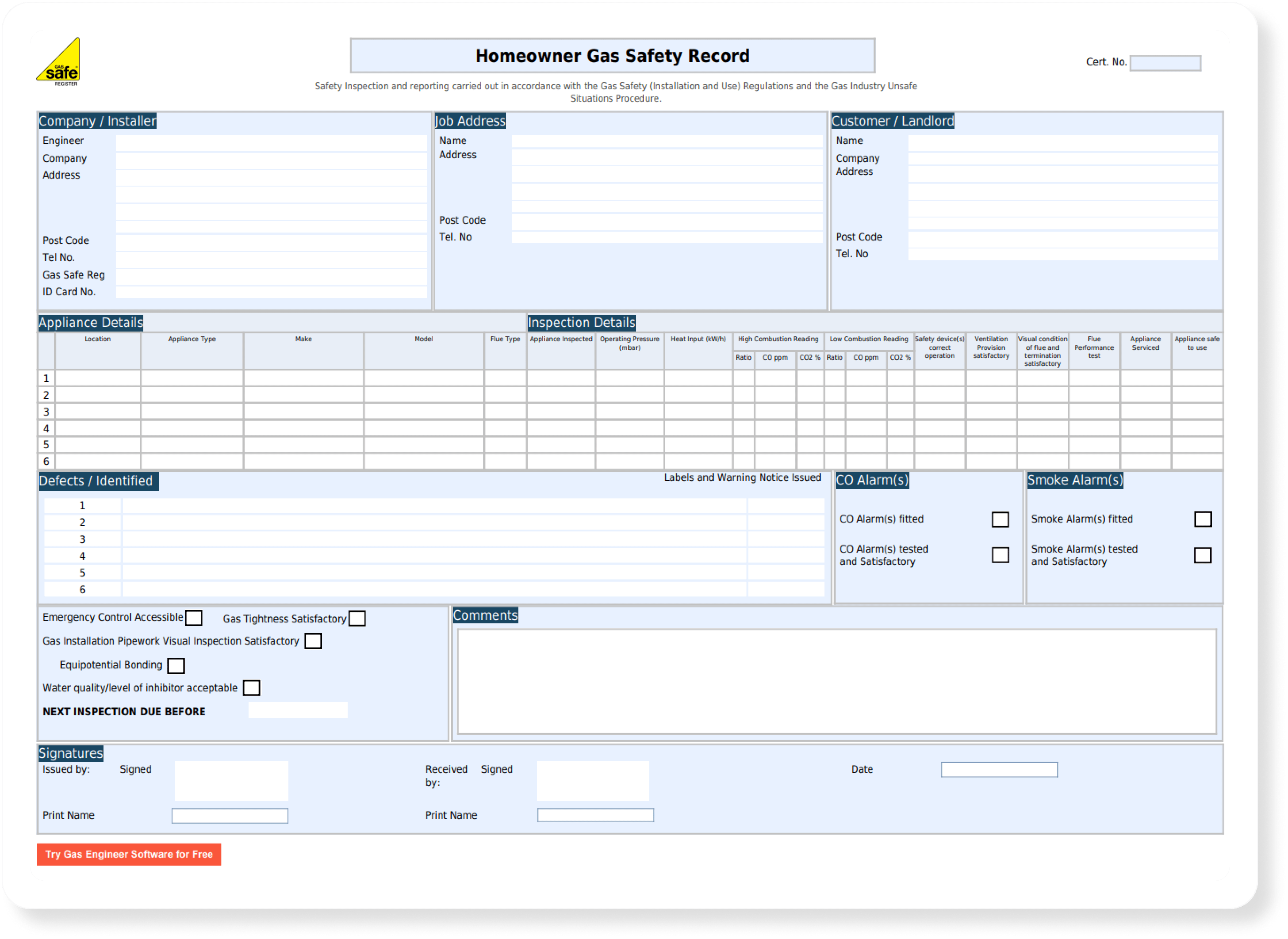

- (17:30) For inspections, make sure you have all that you need: certificates, stickers, a calibrated analyser, stop ends, disks, and so on.

- (19:20) Make sure you are familiar with the appliance that you’re going to be working on while getting inspected.

- (21:45) Inspections are broken into two parts: the practical side and the technical assessment. It will be around 20 questions picked from the qualifications you have.

- (22:16) If you have a qualification, you will get asked questions about it – even if you don’t use the qualification in your work.

- (24:20) It’s open book, so you can take your time to find the answer. Don’t guess it.

Can you lose your registration?

- (25:30) Inspections are not there to catch you out. You’re not supposed to know everything, but you’re supposed to be able to find it.

- (26:50) A fail can lead to a competency inspection, which is a little trickier.

- (28:30) Losing your registration is not very common. You’re more likely to lose it by ignoring inspections.