What We Learnt From Our Interview With a Gas Industry Expert

![[Featured Image] Gas Safe inspector-min 3 things that not all gas engineers know about](https://gasengineersoftware.co.uk/wp-content/uploads/2023/08/Featured-Image-Gas-Safe-inspector-min.png)

74% of homes in the UK are connected to mains gas. These households depend on safe gas appliances and, as a result, the gas engineers responsible for inspecting and servicing them too.

Recently, we were fortunate enough to have the chance to sit down and chat with one of the gas industry’s leading experts.

We talked about everything from features in Gas Engineer Software to whether engineers should be checking smoke alarms. But one thing that stood out was his concern that an alarming number of gas engineers are overlooking a few vital safety checks as they complete gas safe certificates.

For customers – landlords, homeowners, and prospective buyers included –, this is a substantial source of concern. But as a gas engineer, it could mean a huge loss of reputation (and even legal ramifications) should something happen to an appliance you or your team deemed safe.

In this article, we’ll talk about these tests, explore the reasons they may be slipping through the cracks, and explain why you need to ensure you and your team are carrying them out.

3 Crucial Safety Checks Overlooked by Gas Engineers

#1 – Flue integrity test

“I’d say probably out of all the businesses – the hundreds of businesses I see – probably 20 or 30 knew what it was when I asked them”

A flue integrity test is designed to evaluate the condition of the chimney flue system. All gas appliances require a secure and airtight flue to prevent gas leaks, which pose serious health and safety risks.

The gas industry expert we spoke to suggested that a significant portion of gas engineers they’ve worked with don’t know what the test really consists of: “I’d say probably out of all the businesses – the hundreds of businesses I see – probably 20 or 30 knew what it was when I asked them”.

While inspecting jobs, they would see engineers checking the flue to make sure it wasn’t physically damaged. But few were actually using flue gas analysers to check the CO2 and O2 content scientifically to analyse for leaks. Here’s a concise video demonstrating the process.

They surmise that this is likely because it’s not part of their training, despite the fact that manufacturer instructions always recommend a flue integrity test as the first step of an inspection.

Consequently, gas engineers need to consider the system as a whole: Even a brand-new and fully functional gas appliance presents safety concerns when fitted into a home with a problematic or deteriorated flue.

One thing to remember is that the risk isn’t always gas leaking from the system out into the property. It is also possible for CO2 to find its way inside the combustion chamber, causing faults and safety hazards.

#2 – Combustion readings at minimum gas rate

“90% of gas engineers don’t do low rate readings”

Using a flue gas analyser to take combustion readings is one of the most important aspects of ensuring an appliance’s efficiency and gas safety. A combustion reading outside of safe guidelines can suggest an issue in the system that could cause immediate problems.

Most boilers can have their gas flow adjusted on high or low fire settings. According to our contact, gas engineers often turn the flow to the maximum when checking the appliance. The thought process here is to put the system under the highest stress to properly test it.

However, it’s always important to take combustion readings at both the minimum and maximum flow rates. From his experience, “90% of gas engineers don’t do low rate readings”, even though most boilers actually tend to fail on a low rate.

#3 – Gas meter safety inspection

“You can’t do a full gas safety check in 10 minutes. That’s not a proper gas safety check”

Back in 2015, Ofgem announced that it was repealing the two-yearly meter inspection requirement. Perhaps unsurprisingly, our gas industry expert has noticed that most gas engineers now disregard gas meter safety inspections.

However, this doesn’t mean that gas meters never have faults that affect the normal operation of appliances. They noted that while gas engineers will do a tightness test and reassemble the meter, few actually check whether an appropriate amount of gas is running through it.

Especially in the current global climate and with gas supply issues becoming more frequent, they explained that it’s important for gas engineers to check the meter thoroughly rather than rushing through the job: “You can’t do a full gas safety check in 10 minutes. That’s not a proper gas safety check”.

In some instances, our source noted that brand-new boilers were fitted only to immediately fail safety checks because the gas supply running through the meter wasn’t high enough for normal operation.

At the end of the day, a gas meter is an integral part of any household gas system and a faulty one can seriously affect the performance of other appliances. Engineers that simply use their U-gauge to check pipework may be missing the underlying issue entirely.

Running a gas meter inspection helps accurately determine whether the problem is with national gas networks like Cadent, appliance manufacturers, or pipework.

How Gas Engineer Software helps with these tests

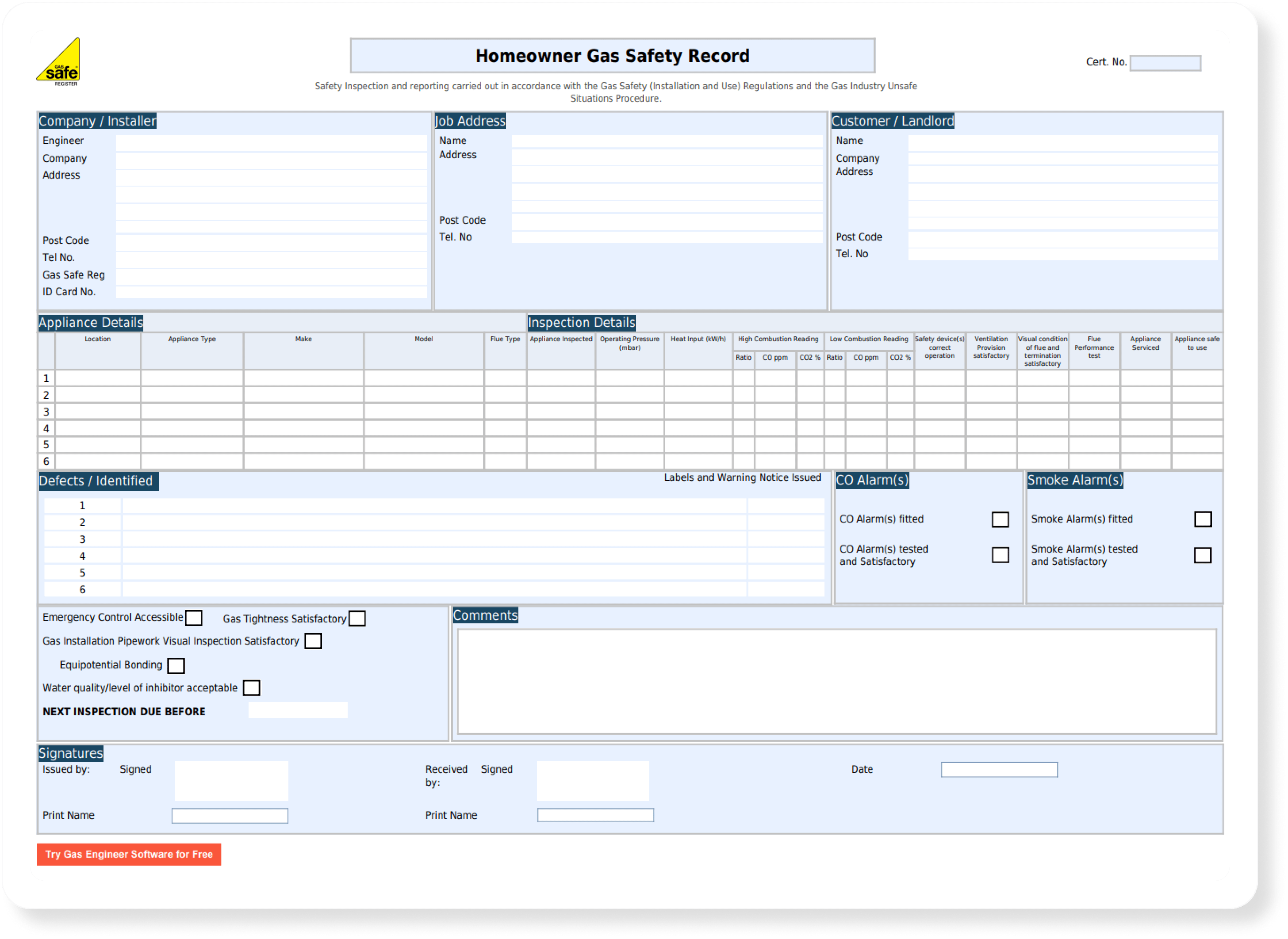

Using software, engineers are consistently reminded of tests and readings they need to take. When completing a gas safe certificate online, they’re prompted by the form to do things like gas rate an appliance on minimum flow – something which is not necessarily there on the paper certificate.

On top of this, software solutions like Gas Engineer Software are designed to simplify and reduce the amount of time spent on paperwork. By giving back time to the engineer, they can afford to spend longer on each individual job and ensure all tests are being completed thoroughly rather than simply scraping a “pass” on the certificate.

Closing thoughts

Gas engineers that sign off on a gas safety check are signing legal documents. Because of this, the ramifications of not completing any of the above tests could be huge for both customers and gas engineers. This alone should be reason enough to ensure they’re getting done properly. They affirmed that “proper documentation and adherence to safety regulations are crucial to protect both gas engineers and consumers”.

As an added bonus, gas engineers that thoroughly carry out these tests can simultaneously use it as a selling point for new customers while building up awareness of the tests amongst other gas engineers.

If you have any questions or concerns, please get in touch with a member of the Gas Engineer Software team.

Next steps:

If you’ve been thinking about implementing software into your workflow to save time, here’s what you can do next:

- Visit our resources centre where you'll find more articles like this one and our free gas rate calculator.

- Start a free trial to see exactly how our software works for your business.

- Watch our video demo to get an idea of how our software works. You can also book a 1-on-1 session with our customer success team for a more personalised experience.

- Know an engineer who's still using paper? Help them and us out by sending our software their way!