Flue Integrity Tests: A Practical Guide for UK Gas Engineers

Every gas engineer deals with flue integrity on a regular basis. A modern room-sealed boiler relies entirely on its flue system not just to expel products of combustion but also to supply clean combustion air. When that system is compromised, even slightly, the appliance can become unsafe.

This guide breaks down what a flue integrity test is, when it’s required, and how to carry one out step-by-step.

What Is a Flue Integrity Test?

A flue integrity test checks whether a room-sealed boiler’s concentric flue system is fully airtight and free from internal leakage.

On a healthy, well-sealed system, the appliance will draw clean air into the inner flue duct while the products of combustion exit through the outer duct (or vice versa, depending on the design).

If seals have failed or joints are compromised, exhaust gases can contaminate the incoming air supply. This leads to poor combustion, higher CO levels, and — in severe cases — a risk of carbon monoxide entering the property.

A flue integrity test uses a combustion analyser to:

- Verify that the air being drawn into the boiler is genuinely fresh

- Check that products of combustion are not leaking back into the air intake

- Confirm CO and combustion ratio results at both maximum and minimum boiler rates

Flue integrity tests are needed for all sorts of jobs: commissioning a new boiler, annual servicing or gas safety checks, after work on the flue system, and much more.

Tools, Equipment and Preparation

Before carrying out the test, ensure you have:

- A flue gas analyser (in calibration and serviced)

- Manufacturer’s instructions

- Safe access to all test points

- PPE and tools for isolation if the appliance must be shut down

Visual checks

Before testing, inspect:

- The full flue route (as much as accessible)

- Support brackets and joints

- Condition of the boiler case and seals

- Terminal siting — check for recirculation risks

How to Carry Out a Flue Integrity Test (Step-by-Step)

1. Zero the analyser in fresh, ambient air.

This ensures the baseline readings are accurate.

2. Set the boiler to maximum rate and allow it to stabilise.

Leave the appliance running long enough for stable combustion (usually 5-15 minutes).

3. Insert the analyser into the air inlet test point and wait for the readings to stabilise.

This may take some time as the air passes through the analyser.

4. Check the air inlet readings:

- O₂ should be ≥ 20.6%

- CO₂ should be ≤ 0.2%

If readings fall outside these limits, the flue seals are likely compromised and exhaust gases are entering the air supply. In this case, you must shut down the appliance and investigate the flue system.

5. Check CO and combustion ratio at maximum rate.

Insert the probe into the flue gas sampling point:

- CO (air-free) should be below the manufacturer’s maximum limit (commonly ≤ 350 ppm)

- CO/CO₂ ratio should be < 0.004

6. Set the boiler to minimum rate (low fire) and allow it to stabilise.

This is a step that some gas engineers skip. In our conversation with an ex-Gas Safe Inspector, this is often what catches engineers out in their inspections — despite being the recommended practise.

7. Re-check CO and combustion ratio at minimum rate.

The readings should remain within safe and manufacturer-specified limits.

Sudden jumps between high and low fire point towards unstable combustion or flue restriction.

Gas Safe regarding a boiler in a concealed chimney/flue system:

“The combustion performance of the appliance is correct in all modes of operation e.g. in both high and low fire rates and complies with the manufacturers instructions or in their absence the guidance offered in BS 7967 – 2015(5) as appropriate.” – Source.

Expected Flue Integrity Readings (and What They Mean)

Air Inlet Test

| Reading | Expected Value | What It Means |

| O₂ | ≥ 20.6% | Air supply is clean and uncontaminated |

| CO₂ | ≤ 0.2% | No products of combustion entering the air intake |

| Any deviation | Outside limits | Internal leakage or failed flue seals → Appliance must be shut down |

Flue Gas at Maximum Rate

- CO < 100 ppm (air-free)

- Below manufacturer’s permitted CO level

- CO/CO₂ ratio < 0.004

These readings confirm stable, efficient combustion under high load.

Flue Gas at Minimum Rate

Readings should remain similarly safe.

Large fluctuations may indicate:

- Fan speed issues

- Incorrect gas valve adjustment

- Partially blocked flue

Flue Integrity Test vs Flue Flow Test vs Spillage Test

Gas engineers often hear these terms grouped together, but they apply to completely different appliance types.

Flue Integrity Test

- Applies to: Room-sealed appliances

- Purpose: Check internal flue leakage and cross-contamination

- Method: Combustion analyser readings at air inlet and flue gas test point

Flue Flow Test

- Applies to: Open-flued appliances

- Purpose: Ensure the flue can remove combustion products effectively

- Method: Smoke pellets / visual confirmation of upward movement

Spillage Test

- Applies to: Open-flued appliances

- Purpose: Check whether combustion products spill into the room

- Method: Spillage mirror / smoke near draught diverter or case opening

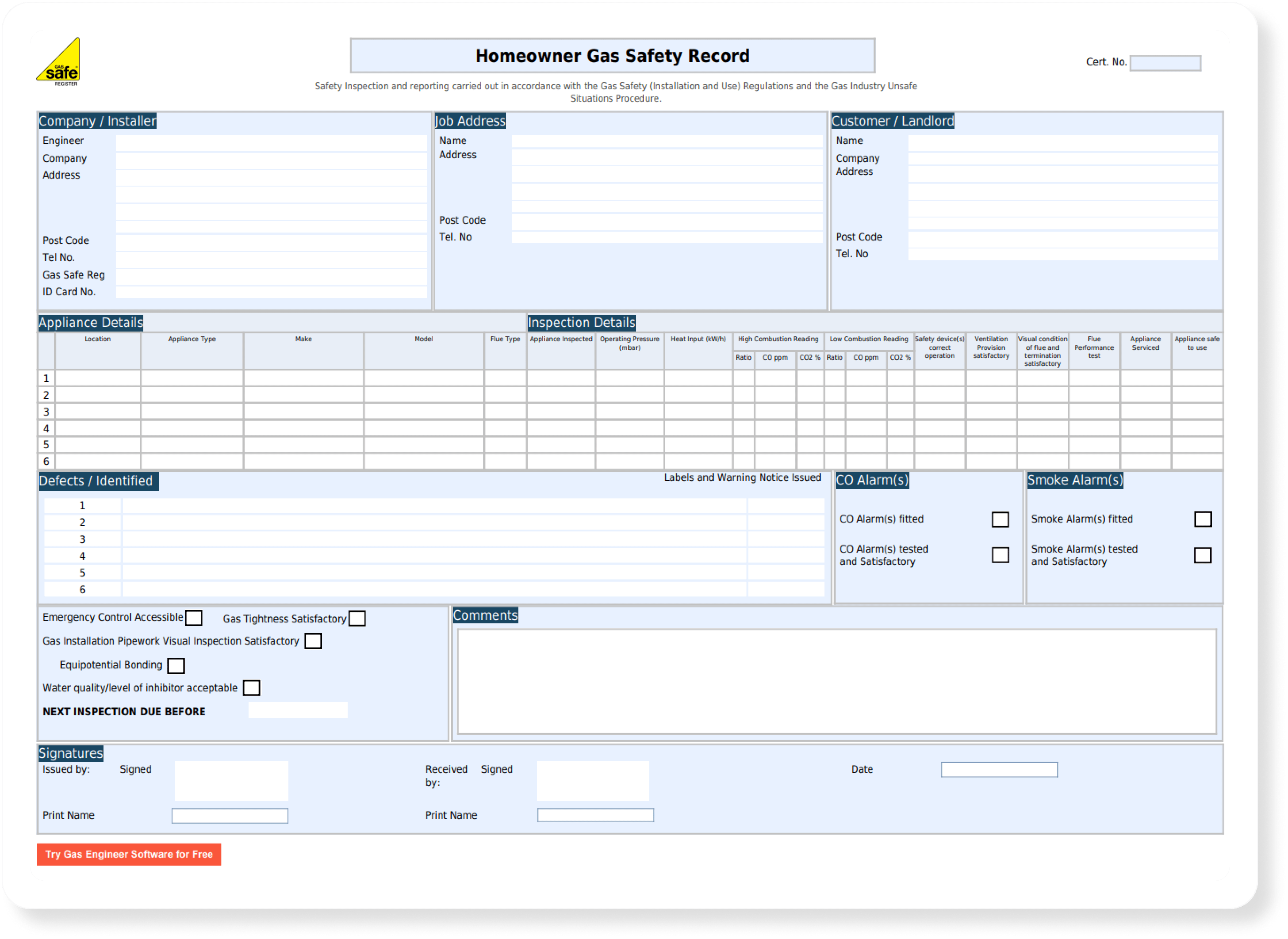

Recording Results and Communicating With Customers

Good documentation is as important as good testing. Using Gas Engineer Software in the field, you can:

- Import analyser readings directly into gas certificates, together with a dated report.

- Add photos of the flue, seals, or terminal

- Keep a service history across recurring visits

- Provide customers with clear, professional records.

- Keep all your business paperwork organised and save hours each week.