What Engineers Get Wrong In Gas Safe Inspections

Gas Safe inspections aren’t meant to catch engineers out. Take your time, know the unsafe situations procedures, and keep any reference documentation you might need on hand for a smooth inspection.

Every UK gas engineer gets their work inspected periodically throughout their career. As long as you follow good safety practices, you should pass with no problem. But that doesn’t mean even the best of engineers get everything right (by the books).

In fact, according to an ex-Gas Safe Inspector we spoke to, several things frequently catch engineers out.

Whether Gas Safe has just contacted you to schedule an inspection or you just want to learn more about the process, this guide is for you. We’ll run through everything you should expect in your inspection, how you can prepare, and what kind of questions catch engineers out.

What to expect on the day of your Gas Safe Inspection

The role of a Gas Safe inspector is to ensure work is being carried out according to the latest safety standards. There are three main sections they’ll look over:

- A technical knowledge assessment

- An inspection of your gas safety equipment

- A practical assessment of your work

From start to finish, your inspection should take 2-3 hours. You’ll need to book two jobs within 30 minutes of your home or office that can be used for the purposes of the inspection.

Note that you will be tested on all of your qualifications, even if you rarely use them.

Questions engineers get wrong on their inspections

KEY TAKEAWAYS

- Your answer might be right in practice, but it needs to be right by the books too.

- Flue integrity tests need to be more than a visual test.

- Keep the unsafe situations booklet with you. Here’s a link to a free download.

- Avoid over-categorising safety issues.

- Remember to fill in minimum gas rates as well as maximum.

- Always do all the safety tests rather than just writing down manufacturers info.

- Brush up your knowledge for gas rating different smart meters.

#1: Tightness testing

With tightness testing, remember that it can be a range. Here’s some advice from the inspector we spoke to:

“New guys know exactly what pressure it needs to be at for how long. Some of the older guys would jump straight into giving me just one number… but you can do the test to a range. They’d just start guessing.”

You can give a valid number for the tightness test, but it’s not the answer inspectors are looking for.

#2: Flue integrity tests

Flue integrity tests are another question many engineers get wrong. Many simply do a visual test, rather than a proper flue integrity test with oxygen readings on the air intake, which commissioning a boiler requires.

“You’re testing the flue seals, you’re testing if the flue is blocked, if there’s an issue somewhere with the flue. But so many people had no clue what I was talking about.”

#3: Unsafe situations

If you’re absolutely certain an appliance is posing an immediate danger, you should cap it. But when you notice something slightly wrong with a boiler (probably justifying an AR classification), it can be tempting to still ID it and prevent the customer from using it… just in case.

Despite the good intentions, you can’t do this:

“Technically, you can’t start capping it off unless you’ve got permission to do so. I was probably guilty of over-categorising before I was an inspector — I didn’t want to leave something that I thought was potentially dangerous.”

Keep a copy of the unsafe situations book with you at all times for extra clarity on what is ID, AR, etc.

The solution is all in how you communicate the issue to the customer. If you tell them their boiler’s at risk, it might just be flue readings slightly out, but could get worse – most people will use their common sense, see the warning notice, and won’t use it. It’s all about how you portray the severity of the issue.

#4: Boiler service modes

It’s crucial you know how to get into the service mode of the boiler you’re working on.

Without the service mode, you can’t properly commission or service a boiler.

“Maximum rate test was normally always filled in – but minimum rate test a lot of the time was left blank.”

Gas rating is easy with Gas Engineer Software. The in-app gas rate calculator keeps a history of your recent recordings, takes away any chance of human error, and adds the results to your certificate for you.

#5: Smart meters

Make sure you know how to operate the smart meter you’re working on so you can do your gas rating properly. There are lots of different types, so stay up to date with technical bulletins and save/print anything that could be useful while you’re on the job or being inspected.

Virtual inspections: What to expect

Since 2022, virtual inspection events have been carried out by Gas Safe in place of some in-person inspections.

Virtual inspections are aimed at engineers who have had in-person inspections before and have demonstrated their competency. They are a bit shorter than typical inspections, taking around 1.5 hours.

How are they different?

You’ll need a laptop, computer, or tablet with a working camera. You’ll get asked about 20 questions to test your knowledge in any areas where you hold qualifications.

As they are done virtually, you will not be tested on your practical skills and it can be done from a the comfort of your own home or a quiet office space.

Gas Safe virtual inspection questions

Virtual inspections will test you on the same topics, including knowledge of your work, unsafe situations, and technical bulletins.

Questions will therefore vary depending on what you are qualified for and according to the inspector.

The types of questions you may get asked include:

- The correct reading on a shown U-gauge

- The recommended minimum size of a warning notice label

- Whether undersized pipework proven to affect the operation of the appliance qualifies as AR or ID

Want to practise with some sample virtual inspection questions and answers?

J D Gudgin from Commercial & Domestic Gas Safe Heating Specialists put together an online practice test, which you can find here.

How to prepare for your upcoming Gas Safe inspection

- Keep a copy of the Gas Industry Unsafe Situations Procedure document (IGEM/G/11 Edition 2). You can reference this in your inspection.

- Learn all the service modes and familiarise yourself with the appliances that you work on. If you know them all off by heart, whenever an inspector asks you to do something you’ll know exactly how to get into the service mode.

- Prepare a checklist for the work you do, either printed or on your phone. Inspections are all open book and, according to Terry, it’s often the less experienced but very diligent engineers who have flawless inspections.

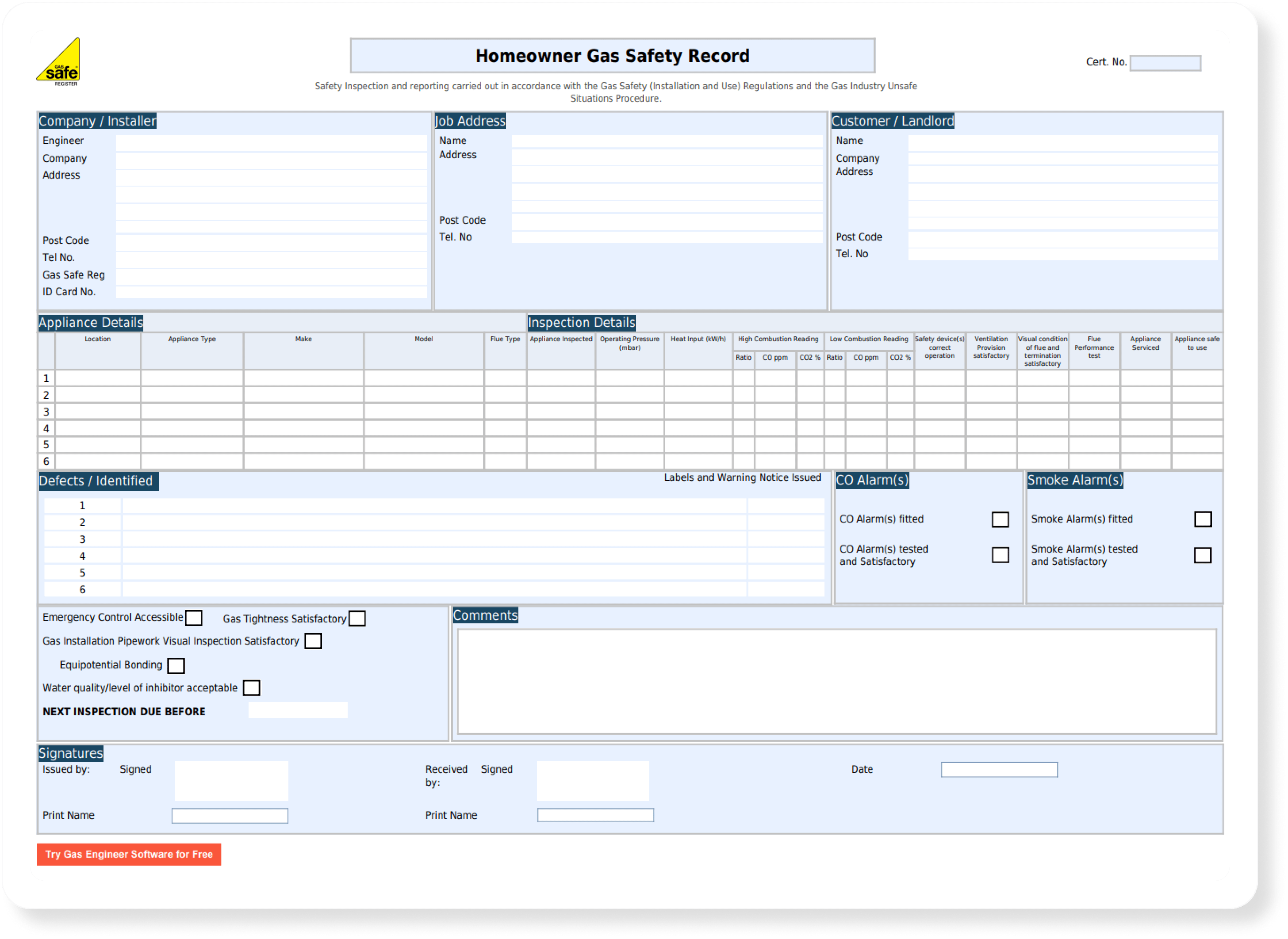

- Look through existing Gas Safety Records if they’re available. Using software makes them all accessible in seconds.

- Read through technical bulletins, as they’re really good sources of information.

- Take the time to do things properly, and don’t take any shortcuts.

Gas Safe inspections aren’t meant to catch you out

“Most are nervous, especially the new guys,” Terry explains. “But I tell people to take their time… No one knows all the answers and as long as you can get a book and find the answer, then you’re doing it as safely as you possibly can.”

This is perhaps one of the most misunderstood parts of safety inspections. They’re not assessments, they’re open book, and they’re supposed to emulate a real-world situation – not a tricky exam paper. “Inspections are not anything to catch people out… No trick questions,” Terry repeats.

“Inspections are not anything to catch people out… No trick questions.”

How we can help with your inspections

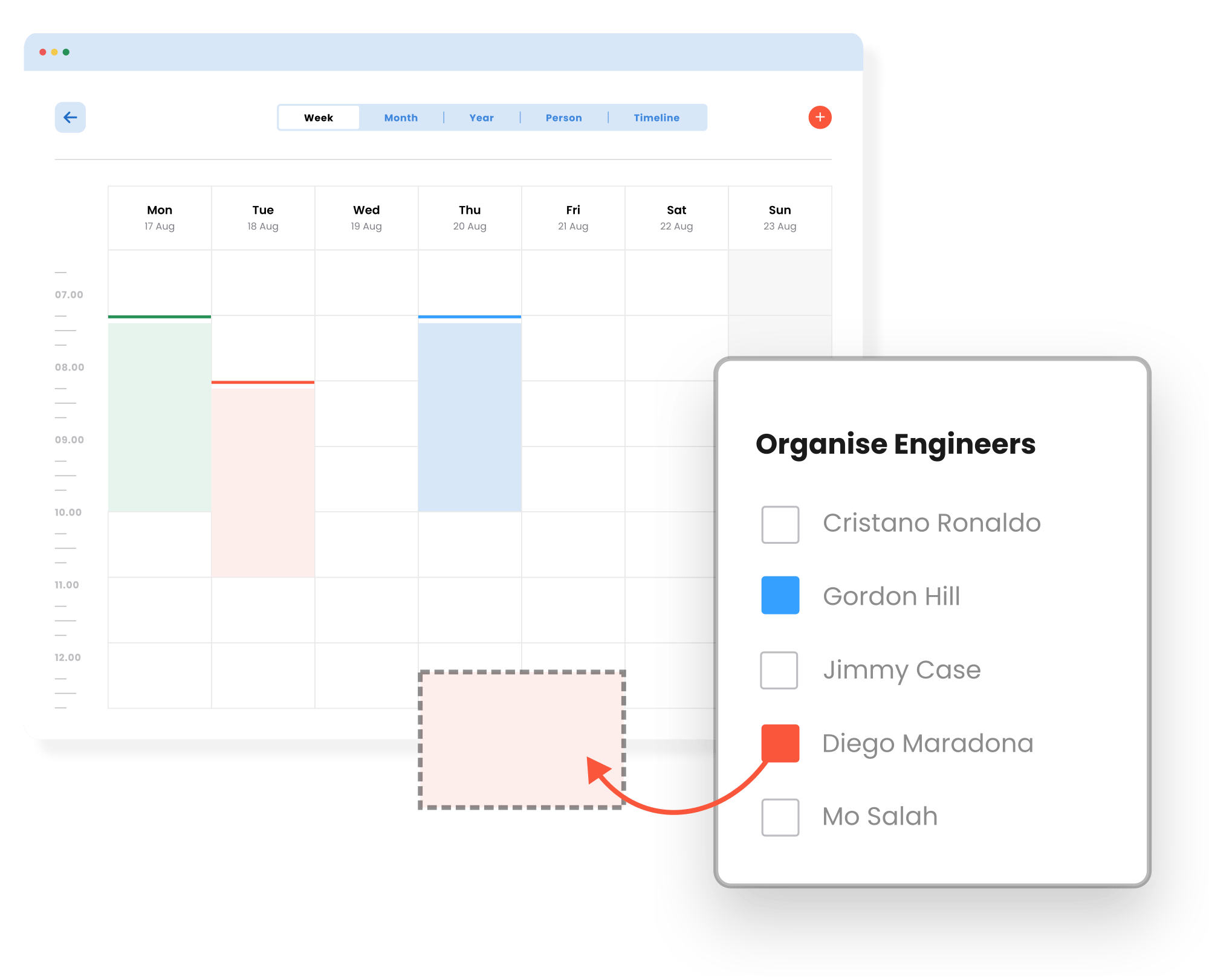

We mentioned briefly the advantage of having our gas rate calculator during your inspection, but Gas Engineer Software offers more than just that.

As an all-in-one job management system, our software gives you everything you need to run your business efficiently. A smooth workflow means less to go wrong and stress-free inspections, but you’ll also have more time to focus on staying up-to-date with industry changes and doing your best work.